Concept, design, and new product development

VPPE will help transform abstract ideas into quality packaging from concept to design to production

Our in-house design staff

creates packaging incorporating both form and function. We will assist you in developing packaging, to maximize profitability by utilizing plan-o-gram space to its fullest capacity. Things to consider for your next project …

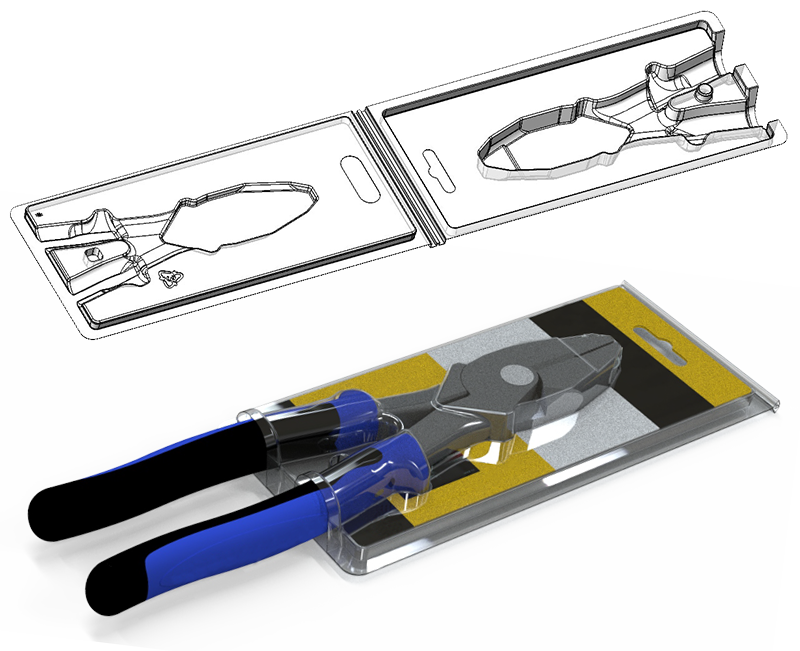

Prototypes

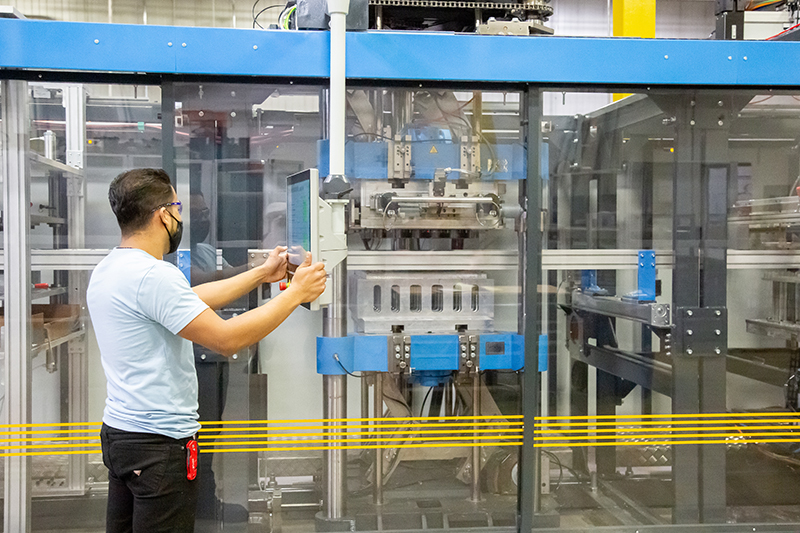

Prototypes will be submitted for approval on all new items prior to fabricating multi-cavity production tooling.

Lead Times

Lead times for the fabrication of production tooling are four to six weeks. Production reorders are produced within two to three weeks or to meet your schedule requirements.

Quality Control

Our production staff performs quality control measures continuously throughout your production run. Blisters, trays, clamshells, and tri-fold packages are all checked for compliance to each customer’s specifications.

Shipping

When shipping, all cartons are bar coded and reflect your purchase order number, item number, description, and piece counts. All cartons are palletized and stretch-wrapped.

Things to consider for your next project

MATERIALS

A basic understanding of the materials used in the thermoforming process, and the capabilities and benefits of each, is an important part of servicing our customer’s needs. Each project needs to be reviewed from the standpoints of functionality, cost, aesthetics, as well as durability in shipping and at retail. Over time, material popularity waxes and wanes, dependent on the needs of the marketplace.

Throughout the 90’s, PVC was the material of choice, based on cost and function. Currently, RPET is the most common material we process, but we also process PVC, HIPS, PETG, PLA, PP, and ABS, as well as different grades and specifications of those materials. Below is a basic primer on the different materials we handle most frequently.

Biodegradables

There has been quite a bit of interest in biodegradable packaging materials, but it’s important to understand that the term biodegradable can be a misnomer, as some materials that are advertised as such, are anything but (such as PLA). There is a big difference between being recyclable, and biodegradable. Once again, VPPE is working with an innovator in the field of biodegradable plastics, and are excited to offer a true bio-resin.

Specialty Materials

In addition to the standard spec materials that we run, most materials are also available with different specialized properties. Not all types of materials are available in these configurations listed below.

FDA (Food and Drug approved materials)

This specialized material is used when the thermoform comes into direct contact with food products, or in some medical grade packages.

- High-Density Polyethylene (HDPE)

- Low-Density Polyethylene (LDPE)

- Polycarbonate (PC)

- Polyethylene Terephthalate (PET)

- Polypropylene (PP)

ESD (Electrostatic Dissipative material)

This type of material is specially treated to dissipate the static charge that builds up on plastic packaging. This material is used in the manufacture of packaging for sensitive electronic components, where a static charge could potentially cause damage to the product. Parts formed with ESD materials are subjected to additional quality control measures, being scanned with a meter that can measure the static charge on a given part. A log is created, and submitted along with the production order.

COEX (co-extruded material)

This is a broad definition of a type of material that has more than one layer of dissimilar materials extruded together. Co-extruded sheet can be as few as two layers, or as many as seven, depending on the application. An example would be co-extruded HIPS, with a utility base layer, and capped with a crystallized high gloss layer. This material is simply an aesthetic choice, and frequently used for POP displays or game trays. This is the most common type of COEX material we currently run.

Within the industry, co-extruded films are frequently used as a barrier material, to prevent transmission of odor or taste through the formed part. Some COEX barrier materials can have as many as seven layers, to accommodate different performance needs of the finished product.

PCR (Post consumer recycled material)

Most recycled materials that we process are in fact post industrial scrap, utilizing waste trim in the extrusion process at the sheet manufacturer, as well as trim scrap from thermoformers who sell the scrap back to the processor. PCR is a certified material that contains a specific amount of post consumer scrap, available in either 25% or 50% content. This type of material is commonly requested for use in specific areas such as California, where regulations require a given amount of post consumer waste included in packaging.

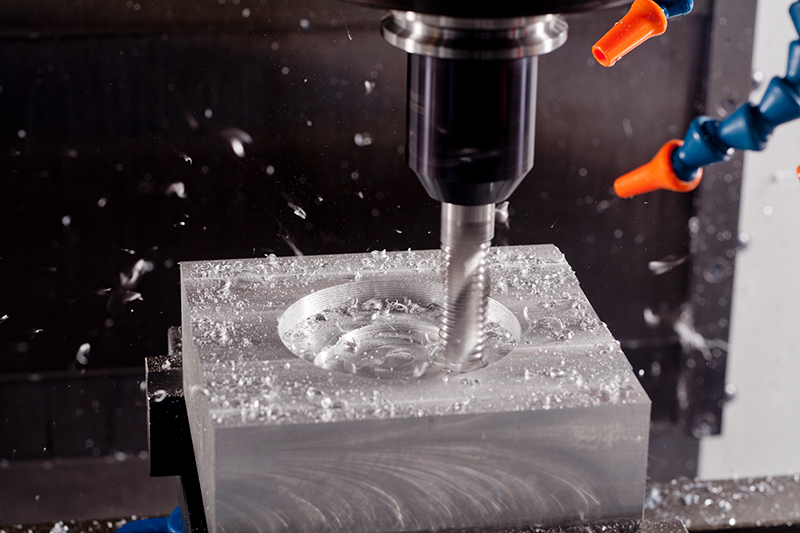

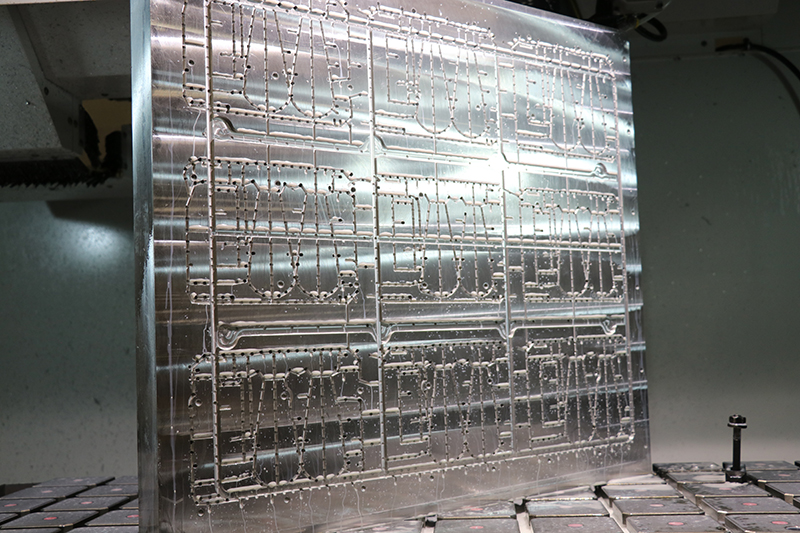

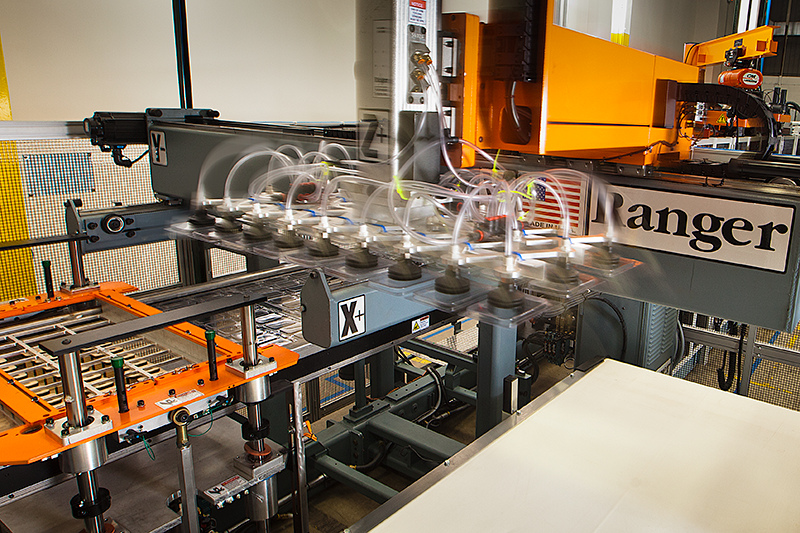

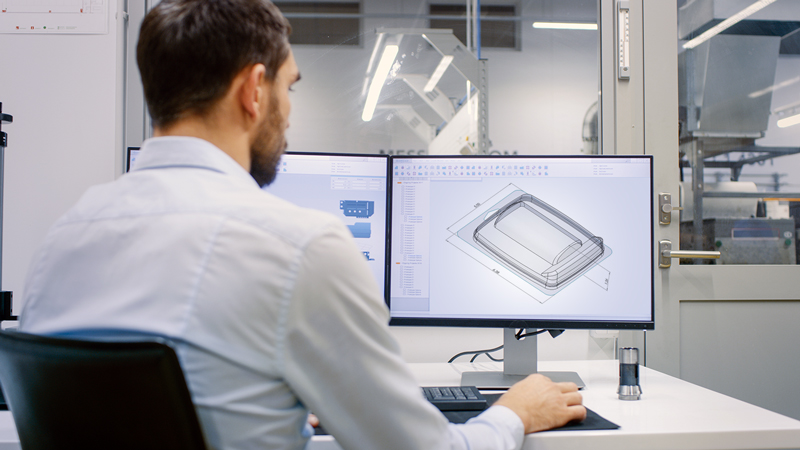

Machine Shop

One area that is a critical component in thermoforming is tooling. We’ve invested heavily in our machine shop, in both equipment and personnel in an effort to achieve complete control over each project. Our engineers on staff design and produce custom thermoform tooling, utilizing a variety of different design software packages, but our primary design and presentation software is Solidworks, the world leader in 3D design. Surfcam is our primary CAM software, which converts design files into data files for CNC machining centers to read.

VPPE offers multiple vertical CNC machining centers with an operating envelope of up to 32” x 64”, providing greater flexibility in tooling design.

All VMCs are connected to our main network, facilitating file transfers and machine operation. These machines are in use 24 hours a day, to better deal with the short lead times typical in the industry today.

In order to shorten design development lead time, we utilize both contact digitizers and laser digitizers.

STAY IN TOUCH

Sign up for our newsletter!